Drive Efficiency: Upgrading Your Construction Machinery with Premium Komatsu Undercarriage Parts

Drive Efficiency: Upgrading Your Construction Machinery with Premium Komatsu Undercarriage Parts

Blog Article

Reliable Solutions: Undercarriage Components for Heavy Machinery

When it concerns heavy equipment, the undercarriage is an important part that commonly figures out the general efficiency and efficiency of the devices. Quality undercarriage components play a considerable duty in guaranteeing the smooth procedure and durability of heavy equipment. From excavators to dozers, each item of tools depends heavily on its undercarriage to stand up to difficult working conditions. Nonetheless, deterioration are unavoidable, leading to potential concerns that can impede productivity and rise upkeep expenses (komatsu undercarriage parts). In this conversation, we will discover the significance of spending in superior undercarriage parts, usual wear difficulties encountered by heavy equipment operators, the advantages of timely substitutes, standards for choosing dependable distributors, and necessary maintenance suggestions to prolong the life expectancy of undercarriage parts.

Importance of High Quality Undercarriage Parts

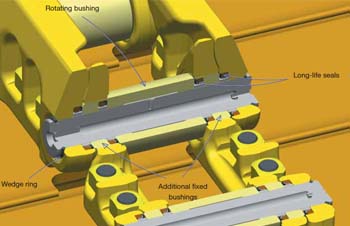

Quality undercarriage components are important elements in making sure the longevity and performance of heavy machinery. The undercarriage of devices such as excavators, bulldozers, and track loaders plays an essential duty in supporting the machine's weight, offering stability on various terrains, and absorbing the impact of unequal surfaces. By buying premium undercarriage parts, operators can substantially expand the life-span of their equipment and minimize the danger of unforeseen break downs.

One secret benefit of using quality undercarriage parts is the enhancement of overall machine efficiency. Sturdy tracks, rollers, gears, and idlers minimize friction and ensure smoother movement, ultimately leading to raised productivity and efficiency on work websites. Trusted undercarriage elements reduce downtime for upkeep and repair services, permitting drivers to maximize their functional hours and job deadlines.

Usual Undercarriage Use Issues

Advantages of Timely Replacement

One secret benefit of timely undercarriage part substitute is raised equipment uptime. By changing used parts prior to they fall short, the threat of unforeseen malfunctions is lessened, minimizing downtime for repair services and upkeep. This positive method not only maintains the hefty machinery operational but additionally protects against prospective damage to other parts that could result from a failing undercarriage.

Furthermore, changing undercarriage parts immediately can boost overall productivity. Spending in prompt undercarriage part Our site replacement is an aggressive strategy that pays off in terms of enhanced performance and decreased functional prices.

Choosing the Right Undercarriage Provider

Picking the appropriate undercarriage provider is a critical decision that substantially influences the performance and maintenance of heavy machinery. When selecting a vendor for undercarriage components, several elements need to be thought about to ensure ideal effectiveness and cost-effectiveness. It is crucial to assess the supplier's credibility and experience in the market. A reputable supplier with years of experience is a lot more most likely to supply high-grade components and trusted solution. In addition, take into consideration the series of products offered by the supplier. A supplier that offers a vast option of undercarriage components for numerous hefty equipment brand names and models can be advantageous as it provides extra options to meet specific demands.

Stabilizing cost-effectiveness, top quality, and integrity is crucial when choosing the best undercarriage provider for heavy equipment. By carefully assessing these aspects, you can pick a vendor that meets your requirements and contributes to the reliable performance and maintenance of your heavy equipment.

Upkeep Tips for Extended Life Expectancy

To make sure an extended lifespan for hefty equipment undercarriage parts, implementing an aggressive maintenance routine is necessary. Consistently checking undercarriage elements such as track chains, idlers, rollers, and gears for deterioration is important. Any indicators of damages or excessive wear need to be immediately addressed to stop additional wear and tear and possible failings. Furthermore, maintaining check my blog the undercarriage clean from dust, debris, and harsh materials can significantly lengthen its life-span. Greasing relocating components according to maker recommendations assists reduce rubbing and stop early wear. Checking track tension and positioning is additionally important to avoid unequal wear on the undercarriage elements. Buying quality undercarriage parts from trusted distributors is similarly vital for guaranteeing long life. By adhering to these maintenance ideas faithfully, heavy machinery proprietors can maximize the performance and toughness of their undercarriage components, ultimately decreasing downtime and functional prices.

Conclusion

In final thought, quality undercarriage components are necessary for the effective operation of hefty machinery. Picking a reliable vendor and complying with correct maintenance practices are read this post here crucial to guaranteeing the expanded life-span of undercarriage elements.

Extreme wear and tear on undercarriage parts of heavy equipment can lead to substantial operational obstacles and raised upkeep costs. Regular examinations, correct upkeep, and timely substitutes of used undercarriage components are necessary to alleviate these common wear problems and make certain the ideal functioning of hefty machinery.

A vendor that provides a wide option of undercarriage parts for various hefty machinery brand names and designs can be advantageous as it provides extra choices to meet certain needs.

By adhering to these maintenance tips faithfully, hefty machinery proprietors can optimize the efficiency and sturdiness of their undercarriage parts, eventually reducing downtime and functional costs.

Report this page